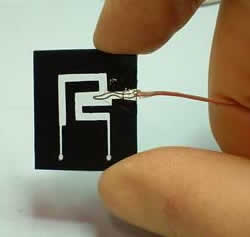

PCR Chip

|

| The PCR chip |

Fabrication Process

Each chip is made up of three small polycarbonate wafers that have been designed using a CAD/CAM software. A computer controlled C02 laser machine is used to produce the different parts by cutting larger polycarbonate sheets. Finally, the different layers are thermally bonded to form the closed chamber that will contain the sample.

An animation of the fabrication process can be viewed below:

click on play to begin

Properties

The chip is characterized by a low thermal mass which allows to it reduce the thermal transients and thus to save time on the entire PCR protocol. To ensure accurate temperature control, a thin K-type thermocouple is introduced into the PCR chamber through a small gap on the side of the chip. This gap is then sealed using epoxy glue.

The internal volume of the PCR chamber is about 10-15 microliters. The chip's .25mm thickness and .5 width allows for samples to be easily loaded and unloaded using capillary action.

A clip of the loading operation can be viewed below.

click on play to begin