Control System

|

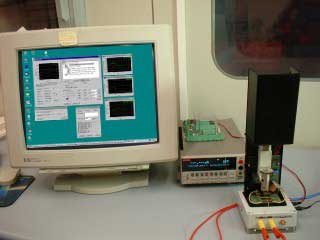

| A view of the control system |

A key requirement for successful DNA amplification is strict compliance with the temperatures and times that define each PCR step. Rapid thermal transients are also required in order reduce the overall reaction time. Given these requirements, a computer-based system has been developed with the intent to achieve both rapid and accurate temperature control. The control system is composed of hardware and software elements designed to heat and cool the PCR chip according to the reaction protocol

|

|

Silicon heater

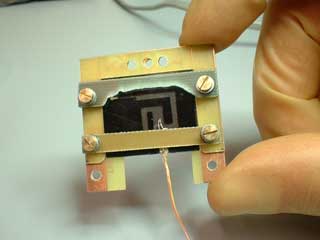

A dissipative resistor consisting of a thin gold coil is used to heat the chip. The coil is spattered on a silicon support, which has excellent thermal properties. Thus, the low thermal mass and high thermal conductivity of silicon result in a rapid and uniform production of heat. Moreover, sufficient thermal contact is also maintained by the use of a small stand which keeps the resistor in constant contact with the PCR chip.

|

|

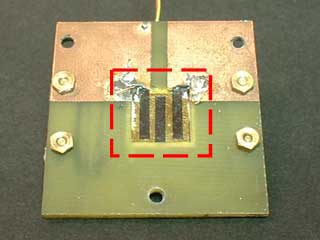

| A detail of the gold metallization on the resistor | The stand built to host the PCR chip |

Control Hardware

Heat is produced by supplying electrical power to the gold resistor. A computer controls this power supply as well as that for the cooling, which is obtained by the activation of a flow of compressed air.

Temperature data are read from the thermocouple using a commercial PC measurement board.

|

|

| Keithley Sourcemeter 2400 computer controlled power supply | NI4351 PC measurement board |

Control Software

The control software operates in a closed loop mode, by constantly monitoring the sample's temperature and activating the heater and the cooler as necessary to follow the PCR thermal cycle. The software was designed to optimize both the speed and the accuracy of the temperature control.

The application also offers functionalities to edit and save custom PCR protocols as well as tools for testing and monitoring thermal performances.

|

| A screenshot of the control and analysis custom software |